PDR (Paintless Dent Repair) for steel car panels uses specialized tools to restore damaged areas without welding or painting, effectively fixing collision-related dents. Technicians employ equipment like plastic dollies, mallets, and vacuum lifts to straighten panels, ensuring high-quality bodywork that matches the original finish. Optimal tool management is key to PDR success: maintaining tools, proper storage, rotation policies, and using high-quality applicators all contribute to precise repairs, reduced downtime, and customer satisfaction in collision repair shops.

“Unleash the potential of your steel panels with the power of Professional Detail Repair (PDR). This transformative process requires a precise set of tools to achieve flawless results. In this comprehensive guide, we’ll take you through the essential techniques and tools needed for successful PDR on steel panels. From initial preparation to final polishing, learn how the right equipment can optimize your workflow and deliver exceptional finishes. Discover our checklist and tips for effective tool management, ensuring every PDR project is a symphony of precision and perfection.”

- Understanding PDR for Steel Panels: Essential Techniques and Tools

- The Right Tools for the Job: A Comprehensive Checklist

- Optimizing Your Workflow: Tips for Effective PDR Tool Management

Understanding PDR for Steel Panels: Essential Techniques and Tools

PDR for steel panels is a specialized technique that involves the removal and replacement of dented or damaged areas on steel surfaces, without welding or painting. It’s a highly effective method for car collision repair and car bodywork services, allowing professionals to restore vehicles to their original condition. Understanding the process requires familiarity with essential PDR techniques and tools designed specifically for working with steel panels.

The key to successful PDR lies in using the right tools for each step of the procedure. This includes specialized tools like plastic dollies, mallets, and PDR hammers, which are used to carefully separate the damaged panel from the vehicle’s frame while minimizing further damage. Additionally, vacuum lifts and suction cups play a crucial role in holding and lifting panels during the straightening process, ensuring precise and effective frame straightening without causing additional stress on the metal. These tools, combined with skilled techniques, enable technicians to perform high-quality car bodywork services, rendering damaged steel panels virtually indistinguishable from their original condition.

The Right Tools for the Job: A Comprehensive Checklist

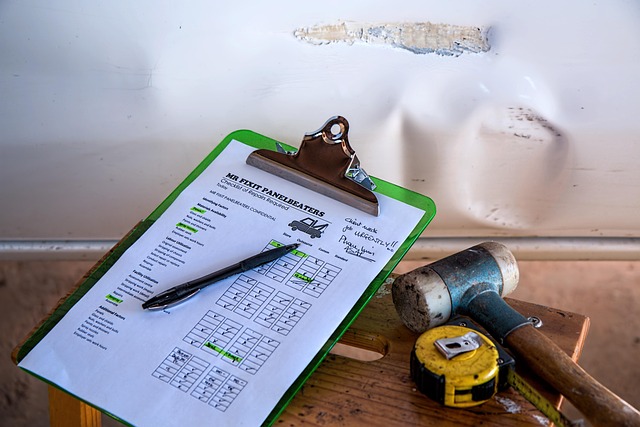

When it comes to PDR for steel panels, having the right tools is paramount to achieving professional and precise results. A comprehensive set ensures that every step of the restoration process is executed flawlessly, from initial damage assessment to final polishing. This checklist includes specialized tools tailored for the unique challenges of steel panel repair, such as prying bars designed to gently remove dents without damaging the surface, and a variety of pullers and tampers for varying dent sizes.

Additionally, consider high-quality applicators and polishes specifically formulated for steel to enhance shine and protect against future damage. Don’t forget protective gear – gloves, safety glasses, and appropriate clothing – ensuring both safety and hygiene throughout the auto frame repair or car body restoration process. Just like in any auto glass repair, the right tools make all the difference, ensuring a seamless, satisfying experience from start to finish.

Optimizing Your Workflow: Tips for Effective PDR Tool Management

To achieve success in PDR (Paintless Dent Repair) for steel panels, proper tool management is key. Optimizing your workflow means ensuring every tool is in top condition and readily accessible. Regularly inspect and maintain your PDR tools to prevent damage and prolong their lifespan. This includes keeping them clean, sharp, and well-lubricated. A well-organized tool storage system facilitates quick access during repairs, minimizing downtime. Implement a rotation policy for heavy-use tools to distribute wear evenly.

In a collision repair shop or vehicle body shop, efficient tool management translates into faster turnaround times and improved customer satisfaction. For instance, having your PDR tools organized on a dedicated cart allows for easy transport between work areas. Additionally, consider investing in high-quality tools designed specifically for steel panel repair to enhance precision and effectiveness, making your car paint repair processes more streamlined and professional.

Mastering PDR for steel panels requires a specific set of tools and techniques. By understanding the essential processes and investing in the right equipment, as outlined in this article’s sections on tool management and workflow optimization, you’ll achieve exceptional results. With the right approach and resources, PDR for steel panels becomes a game-changer, ensuring a smooth, efficient, and professional finish every time.